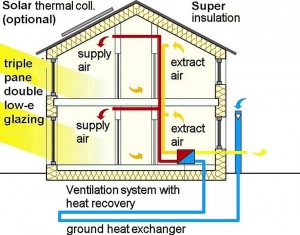

In the construction field when the structural works comes to an end many other works comes in action simultaneously. The main thing among those is impermeability (air-tightness/water-tightness) of the entire structure. It is important because the interior works can be started only when the structure is air-tightness. Otherwise in the extreme cold the materials like plasterboard gets ruined as it cannot resist to low temperature and moisture.

In this project the impermeability is done by bituminous waterproofing which is the mixture of Asphalt and vapor barrier. This starts with a thin layer of enamel (varnish : eng; vernis :fr) of around 2mm thick. This helps to make the good contact between the concrete floor and the the vapor barrier, some millimeter thick bituminous product: elastophrène.

Fig: enamel (vernis) , 1st layer

Fig: enamel (vernis) , 1st layer

Fig: bituminous product, 2nd layer

Fig: bituminous product, 2nd layer

When this is done an for the raised concrete structures like for solar pannels etc isolation is done by the rockwool and a layer of elastophrene as shown in the figure.

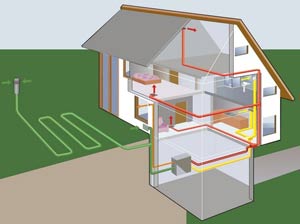

Till this stage on the floor two layers are already put on. This is followed by the isolation. The structure must be isolated otherwise condensation can take place inside the structure and it can damage the materials. Condensation takes place if there is high difference of temperature in short distance and lack of waterproofing materials. So to avoid calculation is done by taking account of thermal resistance of each materials. In this case of impermeability, a product called EFIGREEN A is used which has the resistance (R) of 4.40m²K/W. As it is width (e) of 0.120m, thermal conductance of this material is, lembda = e/r = 0.027 W/mK.

This value obtained is of the good materials that are currently used in market for low energy consuming buildings.

Fig: isolation (EFIGREEN A) , 3rd layer

Fig: isolation (EFIGREEN A) , 3rd layer

Once the isolation is on place this is again covered by thin bituminous product called elastophrène.

Fig: Elastophrene , 4th layer

The 25mm of hot asphalt is then poured from above. The impermeability obtained is of the mixed properties of Asphalt and elastophrene.

Once the asphalt is poured a good finishing is required in the upraised concrete structures and on the edge of the structure as to avoid water penetration. This is done by the same bituminous product as show in the figure.

This will minimize the risk of water penetration in the isolation and in the building. The water penetration cause a big damage as it rest there till winter and it can turn into glace where the volume goes high and many fissures may create on the surface which is sufficient to damage the whole impermeability.

But in some areas impermeability is done without isolation. That means a layer of elastophrene is put just above the layer of enamel and asphalt is poured on. This can be done where there is no risk of condensation. That means if the zone just below is non heated zone like parking, there is no risk of condensation and isolation is not mandatory. In this project this is done in the area of future garden(in fig.) because the level below is parking (non-heated area)